Last Updated on March 6, 2024

3D printing technology has been making enormous strides of late. With complex objects such as parts for aerospace, prototype pieces for mechanical designers, futuristic prosthetics for Olympic athletes, human organs for transplant, and intricate jewelry, all fabricated almost as if by a Star Trek replicator, no wonder some have hailed it as a new industrial revolution. For consumers who are eager to get involved in 3D printing, this article provides an introduction to some basic information before purchasing a 3D printer for home or garage.

3D Printer Types

The 3D printing process starts with creating a 3D model in a CAD program. Next, a specialized piece of software slices the model into layers to be successively printed and generates an STL file containing the layer information that is sent to the printer. Several methods are available to create the 3D printed objects.

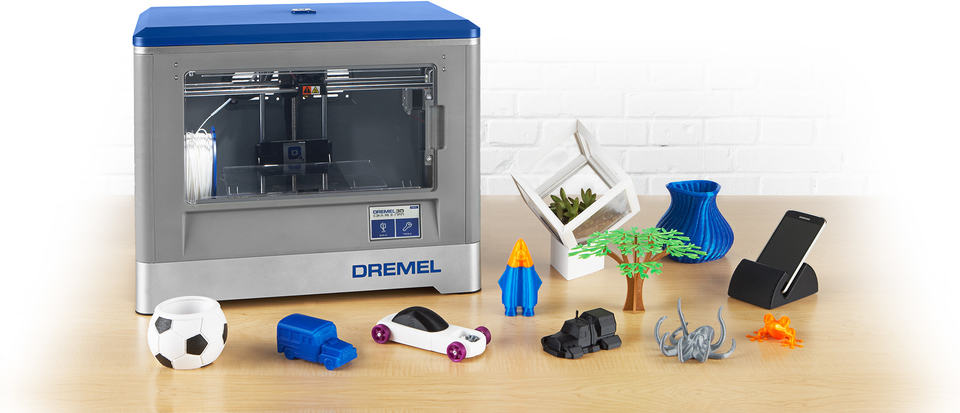

Fused Deposition Modeling (FDM) is the most common 3D printing method used by desktop 3D printers and builds parts with production-grade thermoplastic of excellent thermal, mechanical and chemical qualities for mechanical engineering and manufacturing. FDM builds objects from the bottom up by heating and extruding thermoplastic filament through an extrusion head that deposits the plastic in X,Y coordinates while the build table lowers the object layer by layer in the Z-direction. Overhanging parts of the object sometimes need support rods that are removed after printing is done. The environmentally-friendly technology is widely used for complex geometries and cavities, for new product development and prototyping in the automotive, medical, and food industries.

Stereolithography (SLA), the oldest of the 3D printing methods, creates smooth surfaced objects and is used by mechanical engineers to verify the fit of a part of a design, or to create a prototype. SLA works by exposing a layer of photosensitive liquid plastic to a UV-laser beam pattern that hardens the plastic and joins it to the existing layer below. Each layer is built on top of the preceding one. As each layer of plastic hardens, the model-building platform in the liquid tank of the printer drops down the thickness of a layer, whereupon the laser forms the next layer. When all the layers are finished, the object must be rinsed with a solvent and baked in a UV oven to finish processing.

Selective Laser Sintering (SLS) differs from SLA in using powdered material in the vat instead of liquid resin. In addition, the object being printed doesn’t need support structures since it is surrounded by powder. The 3D print material can range from nylon, glass, and ceramics to aluminum, silver, or steel. SLS requires the use of expensive, high-powered lasers and is more common in manufacturing than with 3D hobbyists.

Selective Laser Melting (SLM) is sometimes regarded as a subcategory of SLS, however, SLM uses a high-powered laser beam to fully melt metallic powders into solid 3-dimensional parts. Typical metals used are stainless steel, aluminum, titanium, and cobalt chrome to create parts with complex geometries and thin-walled structures with hidden channels or voids for aerospace and medical orthopedics.

Electronic Beam Melting (EBM), in contrast to SLM, uses a computer-controlled electron beam under high vacuum to fully melt the metallic powder at high temperatures up to 1000-deg C. EBM is slow and expensive, using pure titanium, Inconel718, and Inconel625 for aerospace parts and medical implants.

Laminated Object Manufacturing (LOM), also a rapid prototyping method, uses layers of adhesive-coated paper, plastic or metal laminates fused under heat and pressure and shaped by cutting with a computer controlled laser or knife, sometimes followed by machining and drilling. The 3D object is created layer-by-layer, and after excess material is cut away, the object can be sanded or sealed with paint. LOM is one of the most affordable and fastest 3D printing methods available to create relatively large parts.

Materials

A variety of materials are used by 3D printers in the form of powders, granules, filaments, pellets, resins, and more under the categories of plastics, metals, ceramics, paper, biological materials, and food.

- Plastic – Polylactic acid (PLA), Acrylonitrile Butadiene Styrene (ABS), and nylon are the most common plastics used, especially among model prototyping or hobbyist users of FDM printers. PLA, an environmentally-friendly, bio-degradable material, is the most commonly available filament today. ABS, also commonly used, was the first material used for 3D printing and is more environmentally stable than PLA. However, shrinkage during print cool down can lead to warping and cracking of the printed object unless a heated print bed is used. Nylon is used as filament in FDM or as powder in sintering; powdered nylon combined with powdered aluminum creates Alumide, also used in sintering. FDM printed plastics, while generally used for consumer-grade products, usually do not have the necessary strength to stand up to demanding settings including airplanes, vehicles, and production machinery.

- Metal – Metals and metal composites are used for industrial grade 3D printing with two of the most common materials being aluminum and cobalt derivatives. Stainless steel is one of the strongest metals used for 3D printing in aerospace and manufacturing and is used in powder form for sintering, melting, and EBM processes as are gold and silver as well as titanium, one of the strongest possible metal materials for industrial applications and aerospace.

- Ceramic – Ceramic materials used in 3D processes are relatively new and need to be fired and glazed after printing.

- Paper – Standard A4 copier paper, used as a 3D printing material by the proprietary SDL process, is an easily obtainable, environmentally-friendly, easily recyclable material supply without post-processing needs.

- Bio-materials – A vast amount of research is engaged in investigating 3D printing of biomaterials for medical applications, such as living tissue to print human organs for transplant, external tissues for replacing body parts, and meat for developing foodstuffs.

- Food – Extruders for 3D printing of food substances are in use for chocolate, sugar, pasta, and meat. Experiments are underway for 3D printing entire balanced meals.

Quality

3D print quality depends on two things: print resolution and print speed. Print resolution determines the level of detail that a 3D printer can produce in the horizontal (X,Y) or vertical (Z) axes. The horizontal resolution is determined by the smallest increment of position that the printer’s extruder or laser beam can make within a layer, while the vertical resolution is the minimal height of a layer that the printer produces in a single pass. The lower the value of the resolution, the higher the level of detail that can be produced. In addition, the finer the details, the longer the print time will become. Resolutions also depend on the method, so while typical consumer FDM printers have vertical resolutions of 0.2 or 0.3 mm, SLA printers offer vertical resolutions of 0.025mm.

For FDM printers, the print speed measures how fast it can move the extruder; the acceleration and deceleration of the printer help prevent the printer from shaking and affect the print speed as well. The quality of a printer is dependent not only on the resolution and speed of the printer, but the materials, method employed, and post-processing; for all these reasons one should look at the output of the printer in order to gauge the printer quality and whether the printer meets your needs.

STL Files

Standard Tessellation Language (STL) files form the bridge between CAD designs and 3D printer hardware by using a mesh of triangles to approximate the surfaces of the 3D model to be printed. CAD systems create the STL files simply by exporting the model into the STL binary file format with a specified precision that represents the closeness of the triangles to the true surface of the design. STL files can be purchased or downloaded for free from a number of online communities where enthusiasts share their 3D printable objects. Among these sites are: Pinshape, Thingiverse, YouMagine, Cubify, My Mini Factory, GrabCAD, DEFCAD, Autodesk 123D, 3DVIA, Cubehero, Bld3r, Shapeways, and Instructables.

Price

When it comes to the prices of 3D printers, the factors that determine that include the quality of the print output, the size of the print object, how long it takes to print an object, the type of materials that can be used, and the 3D printing technology. There will be a trade-off between print quality and print speed, with a frequent choice between printing quickly at lower quality or more slowly with higher quality prints.

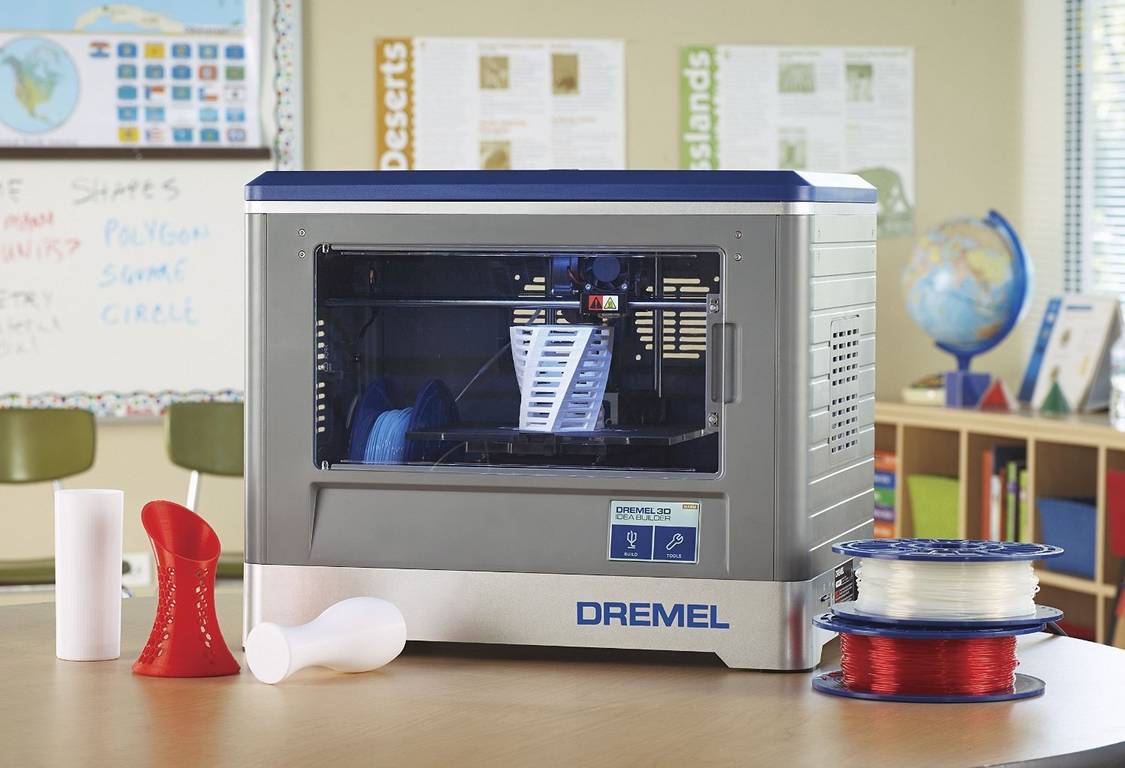

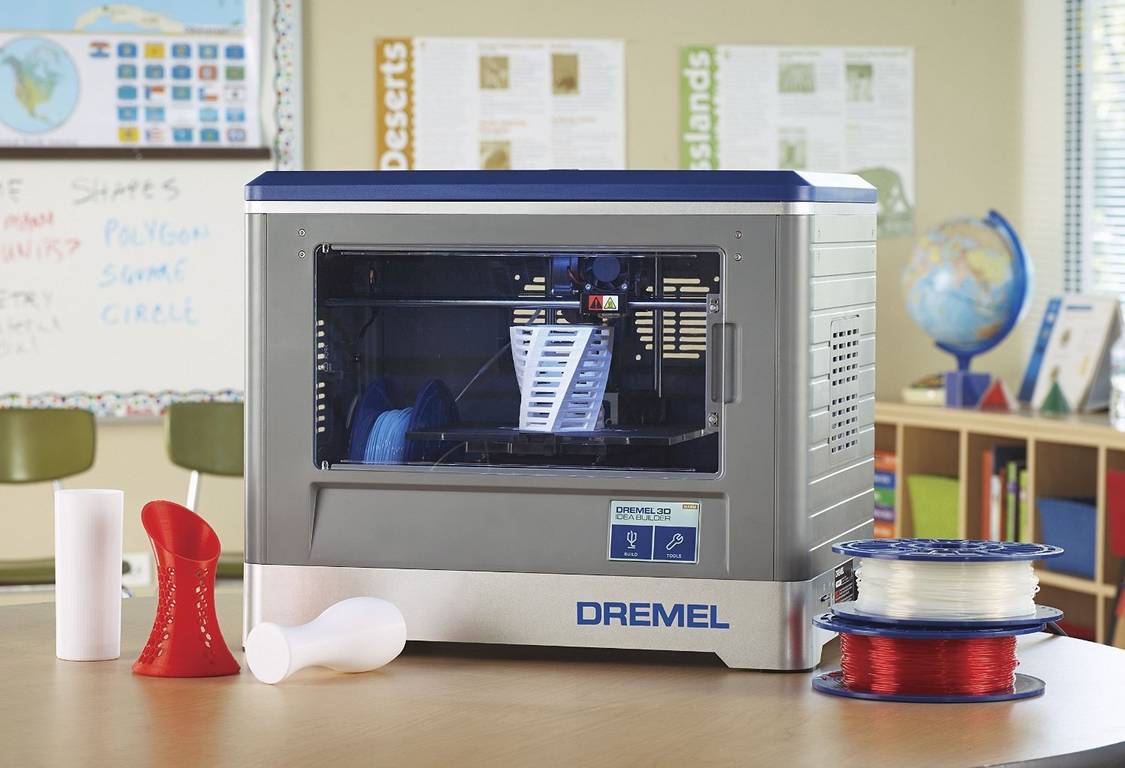

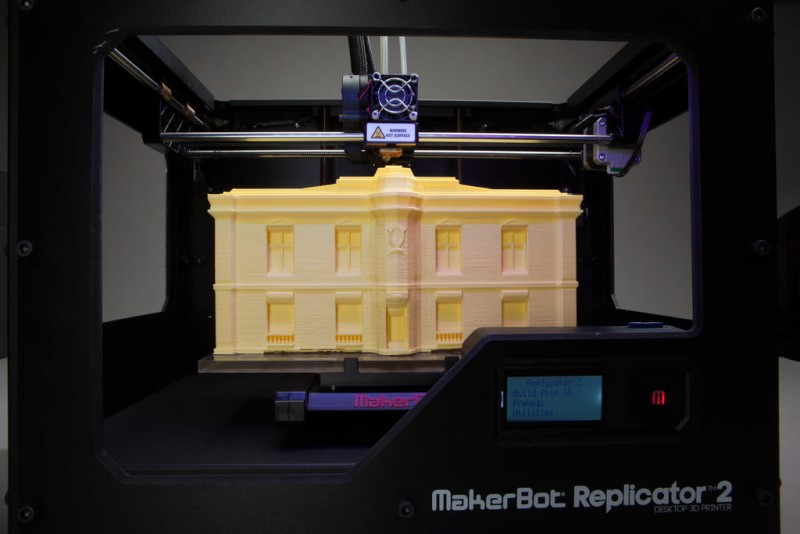

Typically, the budget class of 3D printers will use FDM technology starting at about $350 for DIY kits, whereas complete budget 3D printers cost near $500 and offer standard PLA and ABS plastics to print a maximum volume around 85 cu in.

Intermediate printers will cost about $1200 and offer a wider choice of materials, print sizes around 240 cu in, and better quality or faster speeds. SLA printers will be available at this price range as well. 3D printers for enthusiasts and professionals can be purchased starting around $2500 for FDM printers that will print 1240 cu in.

Numerous SLA or DLP printers are priced from this range; 3D printers of various technologies and advanced production capabilities are priced from a few $K up to a ceiling around $850,000. 3D printers, like office printers, are commonly sold separately from the materials required to print the products. Nonetheless, advancing technology and heavy competition in the 3D printing industry assure that printer capabilities and features will advance while prices continue to drop.

Conclusion

Consumer level 3D printers are likely to employ the FDM process of creating objects layer-by-layer with plastics such as PLA or ABS, although 3D print objects can also be formed from a range of materials such as metals, wood, ceramics, paper, and bio-materials including living tissue, or even food. The quality of the print output is dependent on speed and resolution, although the process itself can affect quality such as the finer details and sharper corners and edges that are available from SLA than from FDM.

STL files are the intermediate step between CAD models and the 3D printer downloadable from online sites and 3D hobbyist or professional communities to enable printing. Finally, the price of the 3D printer without materials ranges from $350 to thousands of dollars, so there is a range of quality, features, and price to fit your needs.