Last Updated on February 22, 2024

Robots are now moving from working behind fixed and caged locations to working harmoniously in stations alongside human workers and also moving from the heavy duty industrial applications to tasks such as providing assistance and augmenting skills.

The Collaborative robots from Universal Robots also called cobots, are redefining the human-robot relationships across the manufacturing industry.

Industry players of all types and sizes are finding strategic reasons to acquire and invest in collaborative robots, and they are smart to do so.

Here are six benefits cobots bring to the table.

1. Increased Human and Robot Efficiency

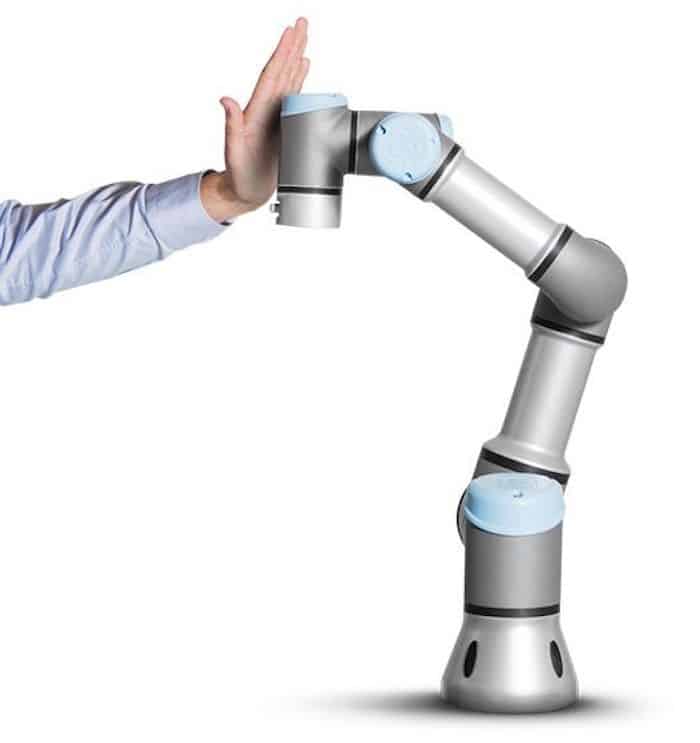

This is the most obvious benefit of working with collaborative robots where the operator loads parts to a conveyor or turntable. Next, he/she leaves the work space, and the cobot arm does its work.

Thanks to the collaborative robots from Universal Robots, workers can give the part directly to the robot and never have to leave the work space thus saving time, cost, and floor space.

There was a study conducted by MIT researchers at a BMW factory and the result was that those teams made of humans and robots collaborating were more productive than teams made of either humans or robots alone.

2. Also Applicable to Small and Mid-sized Manufacturers

There was a misconception that robots are only useful or realistic for large industrial manufacturers. However, that is not the case anymore.

Automated equipment can now be used with small to mid-size companies by using smarter and more accessible collaborative robots.

These smaller industries stand to benefit from cobots and their various industrial applications such as assembly, loading/unloading, packaging, sorting, dispensing, sanding, and polishing.

These types of applications and processes will continue to benefit as long as collaborative robots are embraced across a range of business sizes.

3. Increased Return on Investment

With today’s advanced collaborative technology, a large number of applications are experiencing an impressive return on investment (ROI) in less than one year when they invest in cobots, human training, and their support.

This is made possible since these robot arms can be adopted to work directly next to their human counterpart without the need for barriers to work around hence less lost time.

When you think about it, it adds up since you are increasing productivity and reducing labor costs while at the same time also implementing these exciting and cutting edge technology.

4. Greater Flexibility in the Human Environment

As already mentioned the advantages of installing robots free of safety cages are endless. To start with, the cobots can work in complex human environments without being encumbered by large cages nor the external sensors and barriers that often accompany them.

This allows industries to deploy them, remove the cobots, or deploy humans within one central work space thus enabling flexibility that is required by a lot of high-mix, low-volume manufacturing facilities.

It also frees floor space thereby lowering the cost of implementing robotics for many manufacturers.

5. They Can Safely Handle Complex and Dangerous Tasks

In special cases where safety and complexity are paramount, not only do cobots work side by side with their human counterpart, but are also able to complete dangerous tasks which the traditional robots or humans simply failed.

Applications such as controlling the motion of surgical tools or lab operations to eliminate human error from causing unwanted motion are at the forefront of the robotics industry.

This has paved the way for humans to rely on the inherent benefits of cobots while improving complex and dangerous techniques.

6. Fast and easy to set-up

Universal Robots has done a great job in reducing the robot deployment time that was previously associated with traditional robots.

These cobots do not need any special electrical installations; just a regular power outlet is enough. It takes less than an hour to unpack the robot, mount and program it to start performing the required job.