Last Updated on March 1, 2024

In today’s world, the engineering design industry stands at the forefront of innovation and technological advancement. This field, deeply embedded in everything from infrastructure to manufacturing, is pivotal in shaping the world’s future. It’s an arena that constantly evolves, driven by the relentless pursuit of efficiency, safety, and sustainability. As the demand for more sophisticated solutions grows, the industry calls for visionaries who can merge technical prowess with practical application.

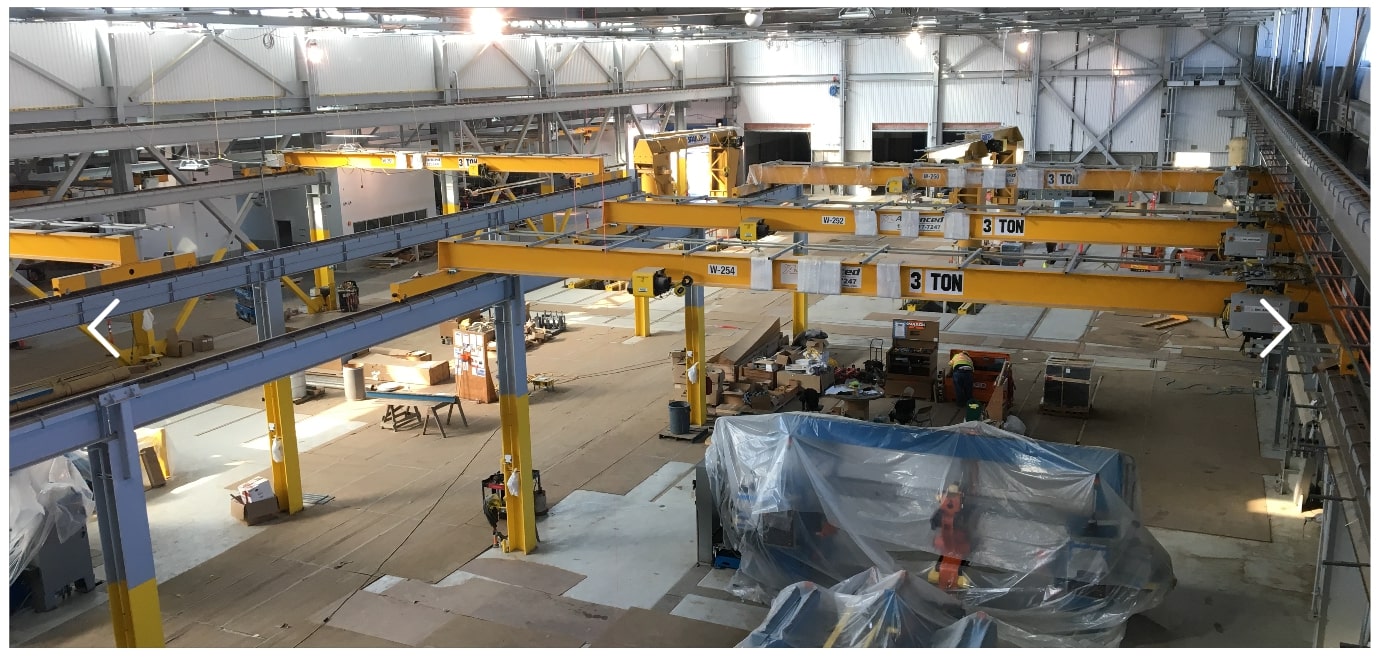

Omkar Sumbe is one such visionary. With over seven years of rich experience in the crane industry, he has mastered the art of engineering design, particularly in the realm of heavy machinery. His roles have been diverse and impactful, ranging from a Design Engineer to a Mechanical Engineer, and finally to a Chief Engineer, reflecting a career marked by relentless progression and continuous learning.

In an exclusive interview, Omkar delved deeper into his extensive industry experience. His story is more than a career trajectory; it’s a narrative of growth, innovation, and leadership in the engineering design industry. For those aspiring to make their mark in engineering, Omkar stands as a shining example of what can be achieved through skill, dedication, and a relentless pursuit of excellence.

Hi Omkar! It’s great to have you with us today. To start with, can you share a project where your expertise in fall protection systems significantly improved safety and operational efficiency?

In my role at Advanced Industrial Solutions, I spearheaded a crucial project focused on enhancing safety and operational efficiency through the implementation of advanced fall protection systems. The project involved designing and integrating innovative fall protection measures for overhead crane operations.

I identified a critical need for improved safety protocols, particularly in areas where personnel were exposed to elevated fall risks during crane maintenance and operations. Collaborating with a cross-functional team, I conducted a comprehensive risk assessment and analyzed the existing fall protection measures.

To address the identified gaps, I proposed and implemented a customized fall protection system incorporating state-of-the-art technologies and adhering to industry standards. This system included a combination of physical barriers, sensor-based alert systems, and employee training programs to mitigate fall risks.

The impact of this project was twofold. Firstly, there was a significant reduction in reported incidents related to falls, contributing to an enhanced safety record for the company. Secondly, the operational efficiency of crane activities improved as the new fall protection measures allowed smoother workflows without compromising safety.

I collaborated closely with the engineering team to seamlessly integrate these systems into the existing infrastructure. Regular training sessions ensured all personnel were well-versed in the new safety protocols. As a result, the project not only met but exceeded safety compliance standards set by regulatory bodies.

This initiative showcased my expertise in fall protection systems and structural design and demonstrated my commitment to fostering a safe working environment while positively impacting operational efficiency. The success of this project underscores my ability to analyze, innovate, and implement solutions aligning with both safety regulations and operational goals.

In your role as a Mechanical Engineer, can you tell us a complex overhead crane design project and the innovative solutions you implemented?

In my capacity as a Mechanical Engineer, I undertook a challenging overhead crane design project at Konecranes, requiring a comprehensive approach to address specific client needs. The project involved designing a heavy-duty overhead crane for a specialized manufacturing facility with unique operational requirements.

I began by collaborating closely with the client to understand their production processes, material handling needs, and specific challenges. This in-depth consultation revealed the need for a crane system with high load-bearing capacity and efficient handling of irregularly shaped and sensitive materials.

In response, I led the design team in implementing several innovative solutions. A key aspect was incorporating a variable frequency drive system, enhancing the precision and control of the crane’s movements, especially when maneuvering in tight spaces and lifting delicate loads.

We also introduced a custom-designed smart control system that used real-time data feedback to optimize the crane’s performance. This improved operational efficiency and enabled predictive maintenance, reducing downtime and enhancing the crane’s overall lifespan.

Addressing the unique layout of the manufacturing facility, we used advanced simulation tools, including finite element analysis, to ensure the crane’s structural integrity and stability under varying load conditions.

Effective communication with the client and our internal project team was paramount throughout the project. Regular progress updates and design reviews ensured that the final solution aligned with the client’s expectations and industry standards.

The successful implementation of these innovative solutions resulted in a crane system that not only met but exceeded the client’s expectations. The heavy-duty overhead crane improved material handling capabilities and demonstrated a 20% increase in operational efficiency compared to their previous system.

This project highlights my ability to navigate complex design challenges, leverage cutting-edge technologies, and collaborate effectively to deliver solutions that meet technical specifications and provide tangible operational benefits to the client.

Regarding the development of estimation and design software at your previous employer, what motivated this initiative, and how did it impact the company’s efficiency and competitiveness?

I initiated the development of estimation and design software to address specific challenges in our project planning and execution processes. This initiative aimed to streamline and enhance the efficiency of our estimation and design workflows.

Before developing the software, the estimation process relied heavily on manual calculations and traditional methodologies. This approach often led to prolonged turnaround times for project proposals and a higher likelihood of errors in the estimation phase.

To tackle these challenges, I proposed and led a cross-functional team to develop customized software that automated the estimation process. This software integrated advanced algorithms considering variables such as material costs, labor hours, and other project-specific parameters. This not only reduced the margin for error but also significantly sped up the estimation process, enabling us to provide clients with more accurate and timely project proposals.

Simultaneously, we developed design software to optimize the creation of preliminary and shop drawings using AutoCAD. This automation improved the accuracy and consistency of our design documents and expedited the overall design phase of projects.

The impact of this initiative was substantial. The efficiency gains realized through the software led to faster project turnaround times, enabling the company to respond more promptly to client inquiries and requests for proposals. The reduction in manual errors also improved accuracy in project cost estimates, leading to more competitive and precise bidding.

Moreover, the standardized design process facilitated by the software contributed to a more streamlined production phase. This enhanced overall project management and allowed for better resource allocation, reducing project lead times.

Ultimately, the development and implementation of estimation and design software at not only addressed specific inefficiencies in our processes but also played a pivotal role in elevating the company’s competitiveness within the industry. The ability to deliver accurate estimates and streamlined designs became a distinguishing factor, positioning my previous employer as a more agile and responsive player in the market.

With 7+ years in the crane industry, how do you incorporate industry codes (AISC, CMAA, ACI) into your design and engineering processes?

I place significant emphasis on adhering to industry codes and standards, such as those from the American Institute of Steel Construction (AISC), Crane Manufacturers Association of America (CMAA), and American Concrete Institute (ACI), in my design and engineering processes. These codes are essential guidelines to ensure the structural integrity, safety, and performance of crane systems. Here’s how I incorporate these industry codes into my work:

Code Familiarity:

- I maintain a thorough understanding of the latest editions of AISC, CMAA, and ACI codes relevant to crane design, staying updated with any revisions or additions to ensure compliance.

Initial Design Considerations:

- When initiating a new crane design project, I conduct a comprehensive review of the specific requirements outlined in the relevant codes, including load considerations, structural design parameters, material specifications, and safety factors.

Load Calculations:

- Adhering to CMAA and AISC standards, I perform meticulous load calculations to determine the appropriate capacity of the crane, ensuring it can safely handle expected loads within specified safety margins.

Structural Analysis:

- Using finite element analysis (FEA) tools, I verify that the crane’s structural components meet AISC requirements, assessing factors like stress distribution, deflection, and overall stability.

Material Selection:

- The choice of materials is critical in crane design. I ensure that the selection aligns with AISC guidelines for steel construction, considering factors such as material strength, weldability, and corrosion resistance.

Concrete Design (ACI):

- In cases where the crane is supported by concrete structures, I incorporate ACI standards into the design process, including considerations for concrete mix design, reinforcement detailing, and structural analysis of supporting elements.

Documentation and Reporting:

- Throughout the design process, I document how each aspect of the design adheres to the relevant industry codes, serving as a comprehensive record and facilitating communication with regulatory bodies, clients, and internal stakeholders.

Continuous Improvement:

- I actively seek feedback from project reviews, inspections, and post-implementation assessments to identify areas for improvement in meeting or exceeding industry codes, ensuring my designs align with evolving industry standards.

Training and Knowledge Sharing:

- I engage in continuous learning and training programs to stay abreast of updates to industry codes and share this knowledge with colleagues, ensuring a cohesive approach to code compliance within the team.

By integrating these practices into my design and engineering processes, I ensure that the crane systems I design not only meet the immediate project requirements but also comply with the highest safety and quality standards set by AISC, CMAA, and ACI. This commitment to code compliance is fundamental to delivering reliable and safe crane solutions in the industry.

Can you share an experience collaborating with cross-functional teams, particularly in the estimation of crane products and structures?

During my tenure at Konecranes, I participated in a major project requiring comprehensive estimation for developing a complex overhead crane system for a manufacturing sector client. The project featured diverse requirements, including heavy-duty lifting capacities, unique material handling needs, and adherence to specific safety standards.

Collaborative Project Overview:

Multidisciplinary Team Formation:

- Understanding the project’s multifaceted nature, I facilitated forming a cross-functional team comprising professionals from mechanical engineering, structural design, electrical engineering, and project management.

Project Kickoff and Requirement Gathering:

- The project kickoff involved collectively defining the client’s requirements and expectations. This included detailed discussions with the client to understand their operational processes, safety standards, and specific challenges.

Integrated Approach:

- The estimation process needed an integrated approach to consider factors like material costs, labor hours, structural design complexities, and electrical system requirements. We scheduled regular collaboration meetings for team alignment.

Continuous Communication:

- Maintaining open communication lines was vital throughout the estimation phase. Regular team meetings facilitated the exchange of ideas, clarification of technical details, and addressing challenges that arose.

Utilizing Specialized Expertise:

- Each team member brought specialized expertise. Structural engineers ensured compliance with codes and standards, electrical engineers addressed control system requirements, and project managers provided insights into scheduling and resource allocation.

Risk Assessment and Mitigation:

- We conducted a thorough risk assessment to identify potential challenges and uncertainties. Strategies for risk mitigation were developed to ensure the estimation was accurate and accounted for potential deviations.

Iterative Estimation Process:

- The estimation process was iterative, with continuous feedback loops and revisions, allowing us to refine our estimates based on evolving project specifications and collaborative discussions.

Presentation to Stakeholders:

- As a team, we prepared a comprehensive estimation report, incorporating inputs from each discipline. The final presentation to stakeholders, including the client, showcased the team’s integrated efforts and provided a transparent view of the estimated costs, timelines, and project deliverables.

Outcome: The collaborative approach was highly successful. The estimation process was not only accurate but also facilitated a seamless transition to design and implementation phases. The project was completed within budget and timeline, and the collaborative effort of the cross-functional team contributed to delivering a crane system that met and exceeded the client’s expectations.

From Design Engineer to Chief Engineer, how has your perspective on crane design evolved, and what lessons have you learned from your diverse experiences?

My journey has been marked by significant professional growth and an expanding perspective on crane design. Here’s an overview of how my perspective has evolved and the lessons I’ve learned through diverse experiences:

Technical Depth and Breadth:

- As a Design Engineer, I focused on the technical aspects of crane design, including structural integrity, material selection, and adherence to industry standards. As Chief Engineer, my perspective broadened to consider the broader implications of design decisions on project timelines, budgets, and overall business objectives.

Project Management and Leadership:

- Transitioning to leadership roles brought a greater emphasis on project management. I learned to navigate complex projects by coordinating with cross-functional teams, managing resources, and aligning engineering efforts with business goals. Leadership skills became crucial in guiding teams toward successful project outcomes.

Regulatory Compliance and Industry Trends:

- With increased responsibilities, I gained a deeper understanding of regulatory compliance and evolving industry trends. Keeping informed about the latest standards, codes, and technological advancements became integral to ensuring our crane designs exceeded industry expectations.

Client Collaboration and Communication:

- Progressing in my career highlighted the importance of effective client communication. As Chief Engineer, translating technical details into clear, accessible language for clients fostered stronger partnerships and became paramount in delivering successful crane solutions.

Innovation and Technology Integration:

- Chief Engineer roles exposed me to the strategic aspect of innovation in crane design. I learned to evaluate and integrate emerging technologies into our design processes to enhance efficiency, safety, and performance, keeping our designs at the forefront of the industry.

Risk Management and Decision-Making:

- With greater responsibility came heightened awareness of risk management. I learned to comprehensively assess risks, make informed decisions, and implement strategies to mitigate challenges, balancing risk and reward in steering projects to success.

Mentorship and Team Development:

- As Chief Engineer, I embraced the role of mentor and leader, prioritizing nurturing talent within the engineering team, fostering a collaborative and innovative work culture, and contributing to the overall success of the department.

Continuous Learning and Adaptability:

- The importance of continuous learning and adaptability became evident. Staying relevant requires ongoing education, embracing new methodologies, and being open to innovation in a rapidly evolving engineering landscape.

Business Acumen:

- My role as Chief Engineer extended to a deeper understanding of business dynamics. Budget management, cost-effectiveness, and aligning engineering decisions with organizational strategies became crucial for the success of projects.

Balance Between Theory and Practical Application:

- While theoretical knowledge is foundational, the practical application of engineering principles became increasingly significant. Balancing theoretical concepts with real-world considerations is essential for delivering practical and effective field solutions.

In summary, my evolution from Design Engineer to Chief Engineer has been characterized by a transition from a technical focus to a strategic, leadership-oriented perspective. The lessons learned encompass project management, client communication, innovation, risk management, and continuous learning. This journey has equipped me to navigate crane design complexities with a comprehensive and forward-thinking approach, ensuring successful outcomes for both the engineering team and the broader organization.

In the ever-evolving field of crane engineering, can you discuss a project where you integrated new technologies, leading to enhanced outcomes?

In my role as Chief Engineer at Advanced Industrial Solutions, I led a transformative project that integrated new technologies into crane engineering. Facing the challenge of optimizing material handling processes, I proposed and implemented a smart crane system using IoT sensors, real-time data analytics, and automation. This system provided real-time monitoring, predictive maintenance alerts, and remote control capabilities.

The outcomes were significant, with improved operational efficiency, enhanced safety measures, and substantial cost savings through predictive maintenance. The client’s satisfaction and increased competitiveness demonstrated the project’s success. This experience highlighted the importance of strategic integration, collaboration with technology experts, user training, and a commitment to continuous improvement in delivering innovative solutions to the evolving field of crane engineering.

What message or advice would you have for aspiring professionals entering the crane engineering industry in the coming years, considering the evolving trends and challenges you’ve observed throughout your career?

Embrace change, continuous learning, and innovation. The field is dynamic, with evolving trends and challenges, and staying ahead demands a proactive approach. Familiarize yourself with emerging technologies like IoT, automation, and data analytics, as these will significantly shape the future of crane engineering.

Collaboration is essential—work closely with cross-functional teams, learn from experts in related fields, and develop a mindset of adaptability. The ability to integrate diverse perspectives and technologies will be invaluable as you tackle complex projects.

Invest time in understanding industry standards and regulations, as compliance is critical in ensuring the safety and reliability of crane systems. Stay informed about advancements in materials, design methodologies, and sustainability practices, as these will increasingly impact crane engineering projects.

Seek mentorship from experienced industry professionals and actively participate in professional development opportunities. Networking within the crane engineering community can offer insights, guidance, and potential collaboration opportunities.

Lastly, maintain a passion for problem-solving and a commitment to delivering solutions that meet and surpass client expectations. In a field where safety is paramount, approach your work with meticulous attention to detail and dedication to the highest standards of engineering excellence.

Remember, the crane engineering industry offers a dynamic and rewarding career path. However, success requires a blend of technical expertise, adaptability, and a forward-thinking mindset. Embrace the challenges, stay curious, and contribute to the continuous advancement of crane engineering for a sustainable and innovative future.